- Glass Railing Systems

- Frameless Glass Railing

- Glass Juliet Balcony

- LED Glass Railing

- Glass Railing Fittings

- Stainless Steel Glass Clamps

- Glass Spigots

- Glass Standoffs

- Railing Tube Fittiings

- Railing Flanges

- Slotted Tube Fittings

- Aluminium Railing Shoes

- Stainless Steel Railing

- Aluminum Railing

- Glass Spider Fittings

- Stainless Steel Fabrication

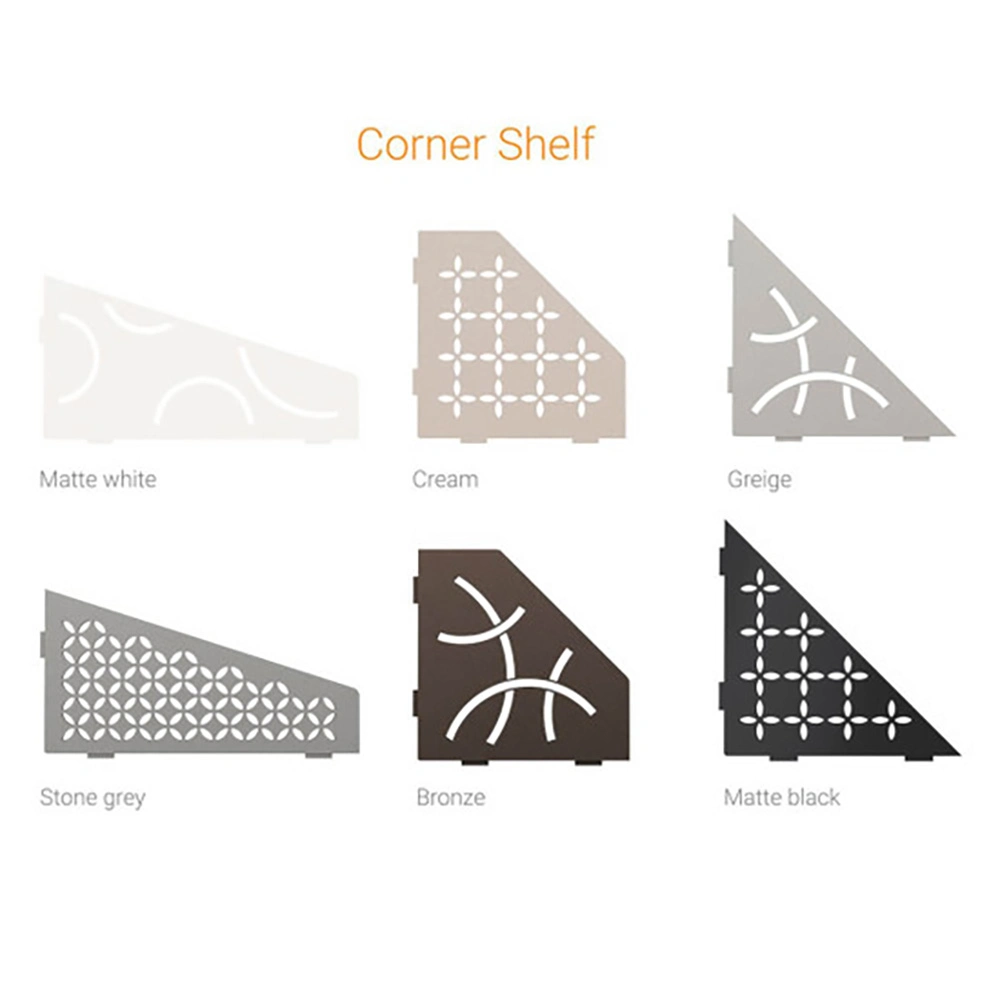

Hot Selling Bathroom Shower Rack Without Drilling Stainless Steel Corner Shelf

Basic Info

| Experience | 12+ Years Experience in Sheet Metal Fabrication |

| Service1 | Provide Integrated Equipment Assembly Services |

| Transport Package | Carton Packing |

| Specification | Customized |

| Trademark | Customized |

| Origin | China |

| Production Capacity | 300000/Month |

Product Description

Product Description

Product name | Stainless Steel Device Enclosure Equipment Housing Sheet Metal Fabrication | |||

Material | stainless steel/Aluminium/carbon steel/Galvanized sheet | |||

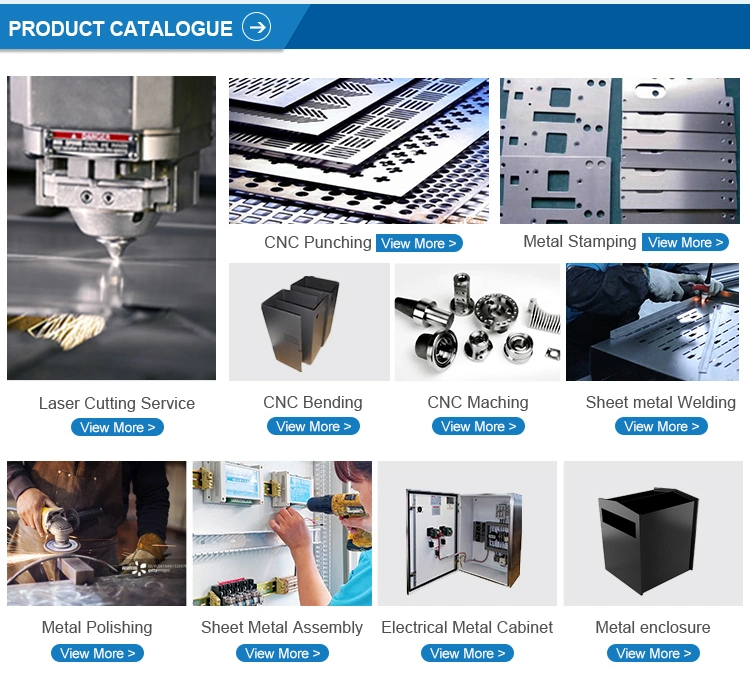

Processing | Laser cutting, CNC punching, CNC bending, Stamping, Welding, Polishing, etc | |||

Surface Finishing | Power coating, Oxidization, Electrophoresis, Galvanization, etc | |||

Size | Customized. | |||

Service | Not only sheet metal fabrication, but also provide comprehensive solution for non-standard self-service devices. OEM & ODM is acceptable | |||

Package | Dongji design or customized. Based on the size and weight of products. We always use carton, wood pallet, wood case or wooden box | |||

Delivery time | 15 days for sample, 30 days for mass production | |||

Payment Term | T/T, L/C, Paypal, Western Union, etc | |||

Usage | Equipment enclosure, Fire box, Metal accessories, etc | |||

Detailed Photos

Company Profile

Factory Main Machinery and Equipment

Laser cutting machines (3 Sets) | Power: 6000W/3000W/2000W Max operation thickness: 0.5-25mm Max operation length: 6000mm Tolerance: ±0.1mm Cutting Speed:10000mm/min (based on 1mm thickness) |

CNC punching machines (2 Sets) | Punching capacity: 30T Tolerance:±0.1mm Punching speed: 800 times/min (based on 1mm thickness) |

CNC bending machines (12 Sets) | Bending capacity: 100T Max operation thickness: 30mm Tolerance: 0.1mm Max operation length: 3200mm |

Mold punching machines (8 Sets) | Punching capacity: 125T Punching with dedicated tooling to assure tolerance High efficiency for mass production |

Welding (30 Stations) | TIG welding, GMAW, Laser welding Can be applied to different thickness sheet metal Stable and high efficiency |

Polishing machines (6 Sets) | Keep the material bright and good luster 8K mirror surface |

Powder coating (1 production line) | Environmental friendly standard line Automatic production line Anti-rust and corrosion-resistant 5 years quailty assurance |

Assembly (2 production lines) | Inner electronic components assembly Complete machine assembly Smart system installation |

FAQ

Q1) Are you a sheet metal fabrication Comprehensive service provider?We are an ISO 9001 certified factory specialized in sheet metal fabrication Comprehensive service provider.Q2) Does Wehouse have any certifications?We have ISO 9001: 2017 and UL Certifications.Q3) What services does Wehouse offer?Our services include sheet metal product laser cutting, punching, , bending, welding, stamping, finishing, and assembly,testing and so on

Q4) What kind of services do you offer?Wehouse offers Sheet metal process for MIG and TIG welding as well as Spot welding and Stud welding services. DongJi has experience in work fabrication for a variety of metals such as Stainless Steel, Aluminum, carbon Steel, Cold Rolled Steel, High Carbon Steel, Hot Rolled Steel.Q5) Does Wehouse provide design and engineering?Wehouse specializes in design and engineering. We can work with you from start to finish on any product you are creating.Q6) Can Wehouse assist to do assemble and testing for products?Wehouse can assist you in assembling any type of product. We have 11 years of experience in R&D, production assembly and testing of smart devices. Our engineering R&D team includes electronic engineers, circuit control engineers, software engineers, test engineers, etc. We are confident that we can assist you with the assembly and testing of any projectQ7). How long should we take for a quotation?After receiving detailed information (your 2D/3D drawings or samples), we will quote you within 3 days.Q8). How about the lead time?General speaking, 15 days for sample, 30 days for mass production. If you have any request, please contact with us.